What is the R-Value of Spray Foam Insulation?

It’s an easy thing to find if you’re talking about a traditional insulation material, but what is the R-Value for spray foam?

You probably feel like you’re being hoodwinked but I promise there is more to it. You see, R-Value doesn’t really mean the same thing for spray foam insulation that it does for cellulose or fiberglass and that’s why it doesn’t get discussed as much.

That’s because spray foam creates an air seal that stops air movement into and out of the home. So the air you pay to treat stays right where you want it and helps you maintain a constant temperature and comfortable house.

But you’re not here for all that.

Here at RetroFoam of Michigan, we don’t want to give you the run-around and we want to answer your questions. Let’s dive right in and talk about spray foam insulation R-Value.

What is R-Value?

R-Value is a measurement of an insulation material’s thermal resistance.

Thermal resistance is…wait for it…the ability to resist heat transfer or loss through conduction. Basically, if a warm or hot material comes in contact with a cold material, the heat is transferred to the cooler surface.

This means the insulation material’s ability to resist heat transfer through conduction – its thermal resistance. Fiberglass and cellulose only work to prevent conduction, while spray foam works to stop conduction and convection, or air movement.

Now, to get into what you came here for – spray foam insulation R-Value.

Spray Foam Insulation R-Value

The R-Value for spray foam insulation can vary depending on the product, manufacturer, and other variables.

Open cell spray foam insulation is R-3.6 to R-3.9 per inch. This R-Value is normal for open cell spray foam.

Closed cell spray foam insulation is R-6 to R-7 per inch.

Not all spray foams are created equal, which is why you’re likely wondering why there is a difference in the per inch R-Value of open cell and closed cell spray foam.

There are a couple of things that affect the R-Value of spray foam – the type of foam, the age of the foam, and how well it is resistant to moisture.

The type of foam insulation affects the R-Value just in how they are made up. Open cell is a lighter material, so the R-Value is lower, while closed cell is thicker and denser so the R-Value is higher. This is because it takes longer for heat to transfer through the closed cell spray foam due to its denser composition.

Now it’s time for an awesome cooking analogy.

When you’re in your kitchen and grab a regular metal skillet, it heats up fast and cools down fast because it is a thinner metal. Now if you’re in my kitchen and we get out the cast iron skillet, it takes longer to heat up because it is a thicker and denser material, much like closed cell.

I just used a kitchen to explain spray foam R-Value. You’re welcome.

Now back to the regular programming.

Another factor in spray foam R-Value is the age of the material. The age of the foam matters because some brands of foam can break down as it ages. As an aside, the foam insulation used here at RetroFoam of Michigan doesn’t break down or degrade over time.

Lastly, the moisture permeability of the foam insulation also plays a role. If the spray foam is saturated in water and the moisture is in the pores, then that water is the conductor for the heat and lowers the R-Value. This happens specifically with open cell spray foam as it is moisture permeable.

Closed cell spray foam is moisture impermeable, so water isn’t able to move through it, thus the R-Value isn’t affected.

Spray Foam Insulation R-Value Chart

Here you see the per inch R-Value of open cell and closed cell insulation, but one inch isn't going to cut it.

You want the air seal that spray foam creates, so to create it you need a minimum of 3-inches of open cell or 2-inches of closed cell. For example, in an area like the roof deck we would recommend 6- to 10-inches of open cell or 4- to 5-inches of closed cell.

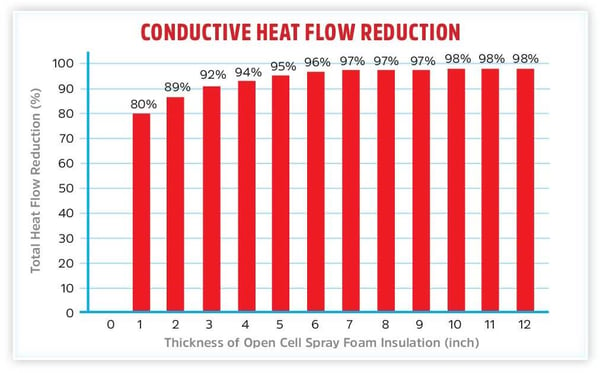

Spray Foam Insulation Air Seal Graph

As you can see here, if you try stacking R-Value on top of R-Value you're wasting money as it diminishes your return.

Once you hit the amount needed to create an air seal, you won't see any more return on investment by adding more foam.

How Does Spray Foam Insulation R-Value Compare to Other Insulations

An air seal is the big game-changer when it comes to comparing spray foam insulation to materials like fiberglass and cellulose.

The thing is that fiberglass and cellulose can’t stop air. R-Value by itself only measures heat transfer by way of conduction, which is advantageous for fibrous materials.

Let’s dive deeper into the air seal foam insulation creates and how that is a game-changer.

It comes down to the way heat travels.

Heat travels much faster through convection or air movement than by conduction. This is where that air seal comes into play.

Fiberglass and cellulose both still allow air to move through them, while foam insulation stops it.

This is why it’s almost more important to have an air seal than to have conductive resistance because what’s the point of stopping heat transfer if you’re not also stopping air movement.

R-Value vs Building Code: Prescriptive vs Performance

When it comes to the prescriptive R-Value and insulation requirements, it really comes down to where you live.

For example, Michigan falls into climate zones five, six, and seven which tend to get cold during the winter.

When the powers that be look at each state’s Energy Code for Insulation and the International Building Code they then prescribe how much insulation you need, how it must be installed, and what insulation materials can be used in what areas of the home, and what depth.

All of this adds up to prescriptive code and the R-Value number you need to reach to hit it.

But with foam insulation, there is another way to pass code and that is through the material’s performance.

Performance is a more complicated way to pass code because you will need to prove the insulation creates an air seal, that it has an aged R-Value, and several other variables.

This can all be done by using programs to check the home’s performance. The insulation contractor will take all of the insulation data, room assemblies, etc., and plug those numbers into a computer program like REScheck or HERS Index. These programs will let the contractor know if the performance passes or fails and they can then pass that information along to the inspector.

Spray Foam Insulation for Your Home

Spray foam and the air seal it creates is what makes it a premium insulation material, not the numbers.

The air seal created by foam insulation keeps air from moving freely into and out of the house. It works to help maintain a constant temperature, which in turn helps your air conditioner and furnace not run constantly.

If you want to learn more about foam insulation, check out the Learning Center on our website.

Related Articles

R-Value vs Air Seal: What is More Important When Buying New Insulation?

Spray Foam Insulation Code Requirements: How to Pass Code Without Meeting Prescriptive R-Value

About Amanda Emery

Amanda previously has worked as a breaking news and crime reporter, TV news producer, and editor in Flint and Detroit. Throughout her career as a journalist, she has won several awards from The Society of Professional Journalists - Detroit Chapter and the Michigan Press Association. As part of the RetroFoam of Michigan family, Amanda uses her experience as a journalist to write content that will help educate homeowners on the benefits of foam insulation. When Amanda isn’t writing, she’s spending time with her husband and rescued huskies. She also loves knitting, making art, cooking, and hosting dinner and a movie night for friends and family.