Injection Foam Insulation vs Spray Foam Insulation: What’s the Difference?

Injection foam and spray foam insulation is like tomato (tomayto) and tomato (tomahto).

Well, sort of.

Unfortunately, some people use the term “spray foam” interchangeably with injection foam, which leads to some confusion. One issue that arises when discussing off-gassing and Volatile Organic Compounds is that some spray foams products do off-gas due to their low VOCs, but the injection foam we use doesn't have any off-gassing.

Expansion rates is another thing that can get confusing when using spray foam interchangeably with injection foam. That's because spray foam does expand and that amount differs depending on whether its open cell or closed cell. Injection foam doesn't expand at all.

Both foam products work the same in that they create an air seal in your home or pole barn, which makes the structure more energy-efficient and comfortable.

The differences come in when it comes to how they are installed, the products, and how they perform.

RetroFoam of Michigan has been installing both injection and spray foam insulation in homes across the Mitten for more than 17 years, as well as the greater Toledo area. We know both products are superior to traditional insulation, and we also know the differences between the two.

In our efforts to educate homeowners, we are going to break down the differences and similarities between spray foam and injection foam insulation.

Injection Foam Insulation vs Spray Foam Insulation Installation Process

Injection foam and spray foam insulation have the same insulating properties for the most part.

Still, the way they are installed is completely different.

Not only is the installation process different, but so are the areas where the materials are installed, and the tools used during installation.

Injection Foam Insulation Installation Process

Injection foam insulation is installed exclusively in the enclosed cavities of existing walls.

It may seem like the process will create a huge mess in your home, but in all actuality, the injection foam can be installed from the outside. This means there is no need to tear down any drywall.

Before installation begins, the injection foam insulation is mixed in the trailer. RetroFoam injection foam is a three-part resin designed to insulate enclosed cavities. As the resin mixes with a foaming agent and water, it transforms into the injection foam insulation, looking much like shaving cream in consistency.

The old insulation in the walls, like fiberglass, doesn’t need to be removed before the installation. Now, if there is cellulose in the walls, the crews will likely remove as much of that as possible before injecting the foam. This is done to ensure the injection foam fills all of the nooks and crannies in the wall.

Now when it comes to preparation for the installation, injection foam has less prep time required than spray foam. That's because the crews work with whatever siding the home has, then they drill the holes, inject the foam, replace the siding and clean up. We'll discuss the spray foam prep in just a moment.

The type of siding a home has can change the installation process.

A home that has aluminum or vinyl siding requires a piece of the siding to be removed all around the home so a hole can be drilled into each stud cavity. The injection foam is mixed in the trailer and runs through a hose with a nozzle to the exterior. The nozzle is placed inside the hole so the foam can be pumped inside the cavity.

Once the foam insulation is then injected into each stud cavity, the holes are filled with a Styrofoam plug, and the siding is replaced.

Brick exteriors are handled slightly differently.

Smaller holes are drilled through the mortar joints between every stud so the foam can be injected. When the cavities are full, the holes are re-mortared.

Lastly, the wood siding process is a little different and a little trickier.

If the siding can be removed, then the same process for vinyl and aluminum is followed. In the case where the siding can’t be removed, holes must be drilled through the wood siding. After the foam has been injected, the holes are filled with wood plugs.

Spray Foam Insulation Installation Process

Spray foam insulation is installed in any open cavities.

This includes attics, crawl spaces, rim joists, and the open wall cavities of new build homes. Spray foam can also be installed in pole barns as either open cell or closed cell material, but more on that shortly.

Most spray foams are made when two liquids combine, causing a chemical reaction to form the polyurethane foam. Those two liquids come from two different drums or containers labeled the “A” side and the “B” side.

The “A” side of a spray foam system is usually made up of methylene diphenyl diisocyanate and polymeric methylene diphenyl diisocyanate. The “B” side is a blend of polyols, catalysts, blowing agent, flame retardant, and surfactants.

When the two barrels are introduced to one another, the reaction is the creation of the spray foam.

The main ingredients in the spray foam we use are water-blown and organic chemical compounds derived from petroleum extracts.

Before spray foam can be installed in an existing home, the old fiberglass or cellulose must be removed. This is done so the spray foam has a nice, clean space to adhere to and can completely fill the space where it is sprayed. Much like injection foam, this ensures every little crevice is filled, and no air can leak through it.

The prep for spray foam takes more time than the prep for injection foam. This is because furniture and other items should be moved out of the area or moved to the center of the room. Then the crew will cover everything in plastic, including the floors and surfaces to ensure no spray foam gets on them.

Now onto the installation.

When spray foam is applied, two hoses are run from the trailer to the home. These two hoses connect to the spray foam gun, where the “A” side and “B” side are mixed in a small chamber.

The foam is then sprayed onto the cavity.

In most cases, open cell spray foam is used in homes. This material expands up to 100 times its original size, so it gets into all the little spaces to create an air seal.

Closed cell spray foam is better suited for the exposed walls of a pole barn, but we will get more into the differences between the two in just a bit.

Injection Foam Insulation vs Spray Foam Insulation R-Value and Air Sealing

Injection foam and spray foam insulation have the same air sealing qualities, while the R-Value can be a little different.

But R-Value doesn’t tell the whole story.

Let’s talk about that air seal first.

An air seal prevents the passage of air or vapor. Creating an air seal with foam insulation can work to block air movement into and out of your home, no matter if it is spray or injection foam.

Creating an air seal is important because around 30 percent of a home’s heating and cooling costs come from air leakage. The ability of spray foam and injection foam to fill all of the nooks and crannies in the attic, walls, crawl space, and rim joist can reduce energy loss in your home, which will reduce your monthly energy bills.

There are several other reasons why creating an air seal is good for your home. Do you or someone in your family suffer from allergies or asthma? Foam insulation’s air seal will keep those allergens outside, making your home healthier.

Another thing to consider is moisture in your home. The foam insulation air seal will keep moisture out of your home, especially in places like the crawl space, rim joist, and attic.

Now there is the R-Value of foam insulation.

Reducing insulation to a number doesn’t tell the whole story. It’s great to know the R-Value of your insulation, but it’s not the revered determiner for all things insulation that you may think. This is because foam insulation creates an air seal, which stops air movement.

But you want to know the numbers.

Open cell spray foam insulation has an R-Value between R-3.6 and R-3.9 per inch. Closed cell spray foam is R-6 to R-7 per inch. Once injection foam is in the wall it lands at about an R-18 in total, but that vary depending on the size of the cavity.

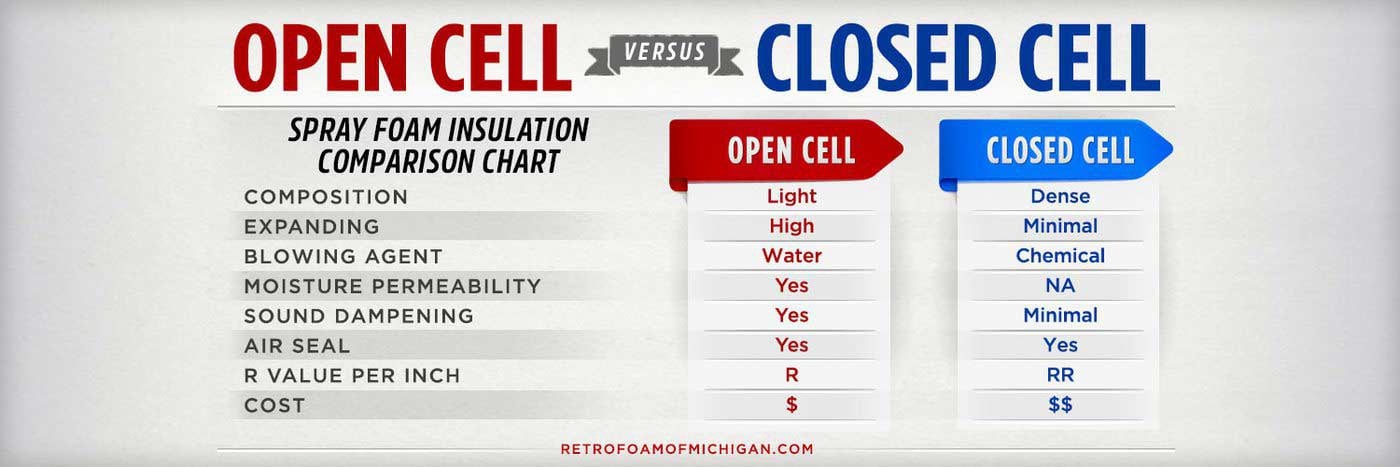

The Difference Between Open Cell and Closed Cell Spray Foam

Spray foam can be either open or closed cell, while injection foam is a non-expanding open cell foam.

While injection foam is an open cell, the reason it doesn’t expand is that you wouldn’t want it to apply pressure to the inside of the exterior wall.

Open cell spray foam and closed cell spray foam have great insulation properties, but there are differences in how they are applied, their efficiency in homes compared to other structures, and how they work.

Open cell tends to be lightweight, pliable and easy to work with. Closed cell is much more rigid and dense. This is why open cell is better for homes because it can move and shift as the home settles, whereas closed cell is nice and sturdy, which makes it a better fit for the exposed walls of a pole barn.

We talked a little already about the expansion rate of open cell, which is another reason why it’s a great fit for homes. Closed cell doesn’t have that same expansion rate and is minimal at best. This is why we recommend it for vans and tiny homes.

Next up – moisture permeability.

That’s an important topic for most homeowners. Open cell is inherently moisture permeable, for example, a good open cell spray foam only retains up to 5 percent of its weight in water.

Closed cell spray foam, on the other hand, is 100 percent moisture impermeable. That might sound like the best option, but this material conceals the leak and you don’t want that if your roof is leaking.

Foam Insulation for Your Home

The biggest difference between spray foam and injection foam insulation is how they are installed, which we discussed above.

Now that you know the differences between spray foam and injection foam, you might want to learn more about the benefits of each. We covered some of those differences here, but there is still a lot to learn.

If you’re interested in learning more about how foam insulation could lead to some great benefits for your insulation project, check out the Learning Center on our website.

Related Articles

Installing RetroFoam into Exterior Walls with Different Siding Types

Open Cell vs Closed Cell Foam Insulation: Which is Better for My Home?

What is the R-Value of Spray Foam Insulation?

About Amanda Emery

Amanda previously has worked as a breaking news and crime reporter, TV news producer, and editor in Flint and Detroit. Throughout her career as a journalist, she has won several awards from The Society of Professional Journalists - Detroit Chapter and the Michigan Press Association. As part of the RetroFoam of Michigan family, Amanda uses her experience as a journalist to write content that will help educate homeowners on the benefits of foam insulation. When Amanda isn’t writing, she’s spending time with her husband and rescued huskies. She also loves knitting, making art, cooking, and hosting dinner and a movie night for friends and family.